Why is tungsten with a high melting point not used in aero engines?

Author:kangbote Time:2021-07-30 18:19:29

Why is tungsten with a high melting point not used in aero engines?

Tungsten metal is the highest melting metal element in the world, with a melting point as high as 3380 ° C. In comparison, the melting point of iron is only 1538 ° C, and the melting point of nickel is only 1455 ° C. Therefore, the filament made of tungsten metal used in the incandescent bulbs we commonly use, because only this metal can withstand the huge heat generated when the current passes through.

△ Metal tungsten is the metal with the highest melting point △

Speaking of high temperature resistance, there may be few places that need to find high temperature resistant materials than aero engines.

After all, aero engines need to generate a lot of energy through extremely intense combustion to drive the aircraft to fly, resulting in the temperature behind the combustion chamber. Needs up to 2000 ° C or even higher.

But we haven't seen metal tungsten in the main structure of the aero engine, not even compounds containing tungsten. Why?

Whether a material can be used not only depends on a certain parameter

High melting point is the advantage of metal tungsten, but a material is far more than the "melting point" parameter, but includes many parameters such as stiffness, strength, density, price, processability ... etc., These parameters are only A bright eye is not enough, but a variety of factors must be considered.

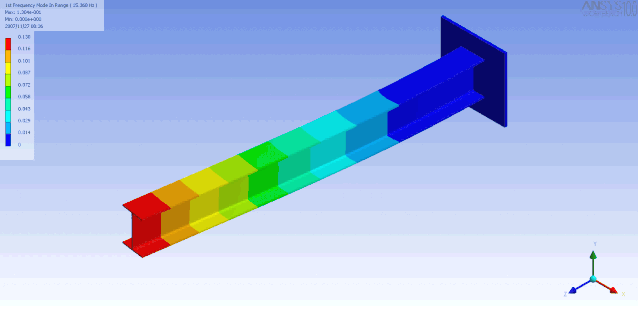

For example, the materials in an aero engine must focus on the material's stiffness, strength, and density. Materials with high stiffness will not deform very much when the structure is under heavy stress. You should know that the rotor in an aero engine may rotate tens of thousands of revolutions per minute. At such a high speed, if the structure has insufficient stiffness , Then there will be a lot of deformation under such a large load, it is easy to cause the engine to function abnormally.

△ The object will deform under the force, so the material rigidity is very important △

High strength means that the material can withstand more force without breaking, for example, the picture below is the static strength test of the metal. The strength of the material is tested by continuously increasing the tensile force until the test piece is broken.

△ Static strength test of materials △

The density of materials is also very critical in aero engines. In addition to the need for weight reduction of the aero engine itself, the more important thing is that the aero engine is going to fly into the sky and is always in high-speed movement. The internal rotor will also rotate at high speed. In the state, the higher the density, the greater the inertial force generated by the material, so it is easier to obtain better performance by reducing the material density. These factors all limit the use of various materials in aeroengines. For example, although carbon fiber has low density and high strength, but its stiffness is not good, it is rarely used in aeroengines; for example, titanium alloy stiffness, strength, The density is good, but it is not resistant to high temperatures, so titanium alloys cannot be used in high-temperature parts ... and so on.

Therefore, even if metal tungsten has a high melting point, the disadvantage is also obvious. That is, the density of metal tungsten is 19g per cubic centimeter, which is twice that of steel and four times that of titanium alloy. So it is difficult to apply such a large density to aero engines.

Tungsten also has a lot of problems in processing

No matter how good a material is, it can only be processed into the parts we need before it can be used. Therefore, the processing performance of a material also greatly limits the use of this material. Tungsten has a high melting point, which is an advantage, but it also means that many of the material processing methods we have been accustomed to are not suitable for tungsten. For example, the related technology of "casting" is difficult to apply to tungsten.

△ Casting is a very common processing technology △

At the same time, tungsten has high hardness and high brittleness, so it is often used to manufacture machined cutting heads, which also represents that tungsten steel is a very difficult material to process. You just think: the machined cutting head is made of tungsten steel, so what should be used to process tungsten steel? Therefore, the above processing difficulties also limit the use of tungsten in aero engines.

△ Cutter head made of tungsten steel △

Most importantly, a high melting point does not mean that it can be used at high temperatures

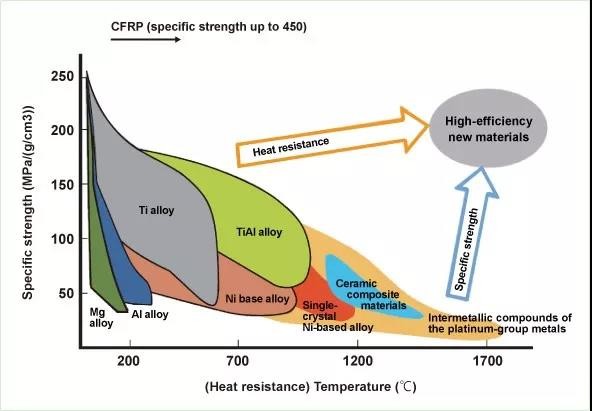

The so-called melting point of a metal means that the metal will melt into a liquid state at a certain temperature. A metal with a high melting point means that this metal can remain in a solid state at a high temperature. But keeping the solid state does not mean that this metal can have the necessary mechanical properties. For example, titanium alloy, although we say that this metal can not be used in high temperature environment (it can not be used at 600 ℃), but in fact the melting point of titanium alloy is often as high as 1600 ℃. So how can a titanium alloy with such a high melting point only be used in a low-temperature environment? The answer is that although the titanium alloy remains solid at high temperatures, its mechanical properties have dropped too much. The following picture is the specific strength of the titanium alloy. It can be seen that the performance of the titanium alloy begins to fall off the cliff after the temperature exceeds 200 ° C.

△ Titanium alloy mechanical properties (gray) decrease rapidly with increasing temperature △

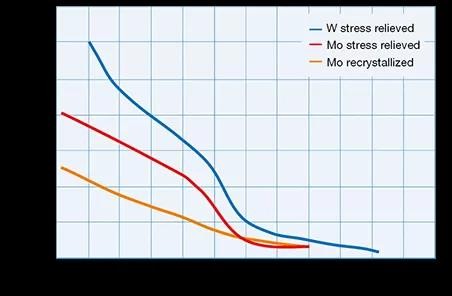

Tungsten has the same problem. Although the melting point is as high as 3380 ℃, but the temperature exceeds 1000 ℃, the performance of its material has dropped very badly, not to mention the amazing density. Therefore, the high melting point of tungsten is precisely "cannot be used".

△ The high temperature performance of tungsten is not so good △

In comparison, rhenium may be a more suitable metal for use in aircraft engines

Rhenium also has a high melting point (3180 ° C), which is slightly lower than tungsten, but compared to tungsten, this metal is not so “brittle” and has better resistance to high temperature creep and mechanics at high temperatures. The nature is not as powerful as the tungsten drop. So even if the melting point of rhenium is lower than tungsten, the density is higher than tungsten (the density of rhenium is as high as 21.04g / cm³), the processing performance is not much better than tungsten, but it is because it still maintains the acceptable material properties at high temperatures , So it is still a super heavy metal that has been initially applied in the aerospace field.

.jpg)

封面.jpg)

.jpg)

.jpg)