Why is molybdenum wire easy to break during online cutting?

Author:kangbote Time:2020-12-26 15:18:58

Why is molybdenum wire easy to break during online cutting?

Transfer from China Molybdenum Industry News Net

Wire cutting is a familiar term, but most people don't know what wire to use, what to cut, how to operate, etc. In fact, another name for wire cutting is wire EDM, which is mainly used to process products with complex shapes and fine structures. Molybdenum wire is usually used as the discharge electrode wire. Why use molybdenum wire as wire cutting electrode wire?

What are molybdenum and molybdenum wire?

Molybdenum is a silver-white refractory metal. In appearance, metallic molybdenum is very similar to tungsten, but the density is only half that of tungsten. Molybdenum is a rare metal on the earth. It is not only an essential trace element in life, but also has a very wide range of uses. Due to its extremely strong interatomic bonding, it has high strength at room temperature and high temperature.

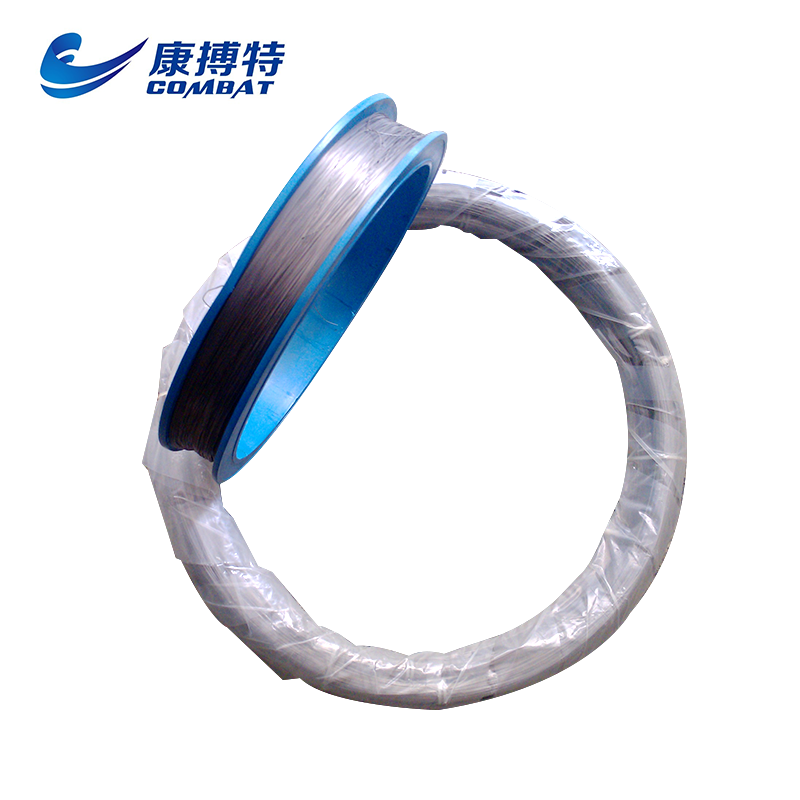

Molybdenum wire is a metal wire with a purity of ≥99.95%, with a diameter between 0.02 mm and 0.35 mm, and has high tensile strength. For industrial workpieces, the cutting precision is high, the wire breakage rate is low, and the processing speed is fast, which can realize stable long-term continuous processing.

However, people in the wire cutting industry know that molybdenum wire breaks inevitably occur in wire cutting. So why does the molybdenum wire break during cutting?

Molybdenum wire tension

Under normal circumstances, the diameter of the molybdenum wire will lose 0.001~0.02mm every time 10000mm2 is cut. After the loss is too much or the service life expires, the molybdenum wire should be replaced in time. Regardless of whether it is a newly used or in-use molybdenum wire, first adjust its tension. If the molybdenum wire is too tight, it is easy to break; if it is too loose, it is easy to short-circuit. To

Wire cutting machine running

The conductive block is usually connected to the molybdenum wire. Since the molybdenum wire contacts the conductive block for a long time and runs for a long time, the contact point will produce grooves, which may break the molybdenum wire. Therefore, the conductive block should be rotated at a certain angle regularly or replaced directly. Furthermore, the molybdenum wire is guided by the guide wheel. The accuracy of the guide wheel will affect the operation of the molybdenum wire, and the bearing supporting the guide wheel will affect the axial and radial runout of the guide wheel, thereby affecting the stability of the molybdenum wire electrical discharge machining.

Cutting technical parameters

The selection of process parameters has a great influence on the loss of molybdenum wire, and excessive loss will accelerate the fracture. Technical parameters should be selected according to specific parts, such as the material, thickness and accuracy of the parts. This parameter is usually selected by the operator based on experience or some intelligent technology. For example, the BP algorithm selects cutting parameters.

.jpg)

封面.jpg)

.jpg)

.jpg)